Let Experts Repair or Replace Your Custom Wine Cellar Cooling Unit in Phoenix

Steve Pantalemon, a member of Wine Cellar Designers Group, spearheaded this wine room cooling unit repair project.

It’s quite hot in Phoenix today. So, you turn on the cooling system for your wine cellar and set the thermostat to its coolest setting. Thirty minutes later, you come back to the wine room and see that the ambient temperature in the wine cellar hasn’t dropped. To add to your frustration, you notice there are molds growing on the surface of the wine shelf. I think it’s about time you call an expert to repair your wine cellar cooling unit.

Existing wine cellar owners and would-be wine cellar owners dread the thought of this scenario. Extremely high or extremely low temperature and humidity in the wine cellar are not good for your collection. If you fail to meet the best conditions in keeping your wines, you’ll end up ruining their quality in the process. That’s why this client contacted Steve Pantalemon. She wanted help to repair the problem with their cooling system.

Cooling System of Client’s Wine Cellar Needed Repair

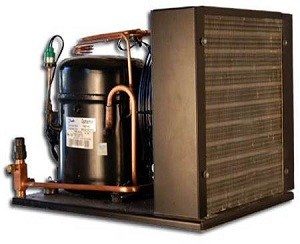

The team had to replace the existing self-contained cooling unit with a more efficient split-type cooling unit for the client’s custom wine cellar.

Molds had already started growing on the topmost part of the wine racking system. The cooling system wouldn’t cool the wine cellar like it was intended to do. The client knew that if this were to continue, it would jeopardize her entire wine collection. She immediately called the team to help fix her cooling system problem.

The client commissioned the team which built her house, to construct the first wine cellar. It’s highly recommended that you hire an experienced and knowledgeable team, like Custom Wine Cellars Phoenix, to build your wine cellar. Unlike a house, a wine cellar needs to maintain certain levels of relative temperature and humidity to store wines in it. And, not all builders and contractors have the required solid knowledge and expertise in creating a wine cellar that is conducive to long-term wine storage.

This wasn’t actually the first time that the newly installed cooling system had failed to refrigerate the wine room effectively. Several cooling units had been installed in the past and yet the client got the same problematic results.

The team discovered that the overall insulation for the wine cellar was insufficient to keep the unwanted temperature fluctuations outside the wine cellar from slipping into the wine room. Additionally, it was found that the self-contained cooling was not broken. But rather the cooling unit was not enough to keep the optimum temperature and humidity for the wine collection.

And for these reasons, the team suggested a total wine cellar makeover to the client, including replacing the cooling unit with one of the proper sizes. She agreed, and we went to work. The new wine cellar builds focused on maximizing insulation within the wine room and efficient regulation of optimum temperature and humidity in the wine cellar.

Types of Wine Cellar Cooling System

There are two basic types of wine cellar cooling systems – the self-contained cooling unit and the split-type cooling unit. Each type of cooling unit has its own distinguishing feature. Choosing what to use depends on your project specification and needs.

The first one is the self-contained cooling unit. This cooling unit is one you’ll commonly see since builders can install it right out of the box into your wine cellar. But, hiring a professional to install it is advisable if you want to make the most of its cooling capacity. It is usually rectangular (sometimes cubical for some models) in shape and you fit it into the wall with its exhaust protruding outside the wine room. All its parts are enclosed inside it, hence, the name. This cooling unit is good for small wine rooms.

Split-type cooling units, on the other hand, have their condenser, coils and other parts separated from each other. Usually, only the vent of the cooling system is visible in the wine cellar. Cables, lines, condenser, evaporator, and other parts of the cooling system are placed in the garage or soffit above the wine cellar. Concealing all the parts will eliminate the bulky appearance of the entire cooling system in the wine room. This type of cooling system produces minimal to zero noise depending on the ducting system installed. For bigger wine cellars, this would be the perfect choice for a cooling system.

Tips to Get the Most from the Wine Cooling Unit in Your Wine Cellar

Determine the R-Value of your cooling unit.

It is essential to check if there are any leaks or gaps inside the wine cellar. The door shouldn’t allow air outside to penetrate the wine room when it is closed.

R-Value is the measure of the capacity of the overall materials in a structure to resist heat transfer in a structure or building. The higher the R-Value, the greater the insulating capacity of your wine cellar. This means that your wine cellar won’t be easily affected by sudden temperature and humidity fluctuations outside its walls. It’s essential that you know the R-Value for your wine room. We’ll do a heat load calculation to figure out what level of insulation they’ll need. It’s one more reason why it pays to work with wine cellar experts.

Drywall alone won’t be enough to maximize the insulation for your wine cellar.

Yes since You can’t rule out that there will always be a possibility that condensation will happen inside the cavity of your wall without any additional insulation applied to it. Condensation in the wall cavity is not wanted. It could directly affect the humidity in the wine room. As a solution, it is advisable to have a spray foam application between wall cavities to retard the formation of water droplets in it.

The total area of your wine cellar is one of the things you should consider before buying a wine cooling system.

As mentioned above, a self-contained cooling unit can refrigerate a small wine cellar. But, for larger areas of wine storage, a split-type cooling unit should be your choice.

Make sure to check the wine cellar for any gaps or leaks.

With the wine cellar sealed, the cooling unit could work more efficiently. It means the unit will work less but still maintain the temperature and humidity. Leaks could lessen the efficiency of the cooling system since air outside would seep in and continuously disrupt the cooling process.

A Successful Wine Cellar Renovation Project for the Team

Steve and his team had to remove the entire wine racking system. They replaced it with black satin stain wine pegs built exclusively by the Custom Wine Cellars Phoenix. Then they installed an Alderwood back panel which included LED lighting in it. For the cooling system, Steve got a WhisperKool ceiling mount split type cooling unit for it. And, lastly, the team crafted a custom wine cellar door with a double-paned glass panel. The door also has a self-sealing mechanism to ensure that the wine cellar is sealed when it closes. To retard condensation and heat transfer within the wall cavity, the team sprayed 5 inches of spray in between walls.

The wine cellar looks more beautiful and elegant now with wine pegs installed. Wines look more presentable now with the Alderwood back panel and LED lighting behind it. The team also built a custom wooden arch to add to the aesthetics. It could also be used as an area for the decantation of the wines. Temperature and humidity in the wine cellar were maintained consistently. There’s no more mold growth on the surfaces of the wine racks.

Our client never had any problem with her cooling system once the team finished remodeling her wine cellar. She no longer had to worry about her wines getting ruined because of the drastic rise and fall of humidity and temperature inside her wine cellar. Changing her cooling unit faster than it was designed to last was a thing of the past now. With the client’s cooling system problem resolved, we take pride to say that the project had lived up to our goal of providing solutions to our clients.

Do you have an existing wine cellar and have any problems maintaining it? Or do you plan to build a wine cellar but are not sure where to start? Either way, call us NOW, and let’s get yours started!